We provide software / hardware customization & OEM service for X Ray sorting equipment

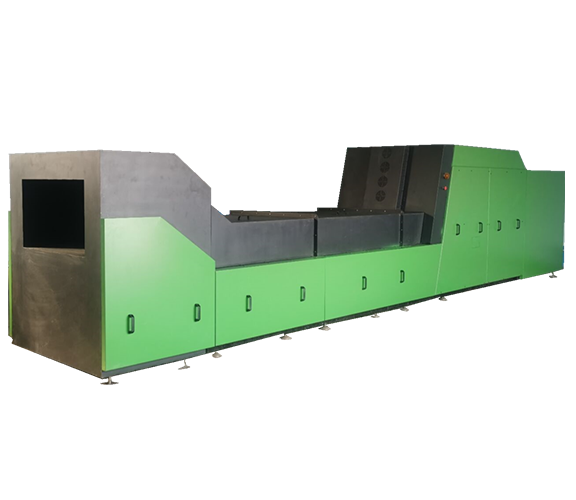

XS-XRT1200

We provide software / hardware customization & OEM service for X Ray sorting equipment

X Ray sorting system with simple structure and high precision

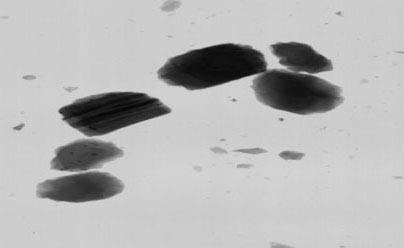

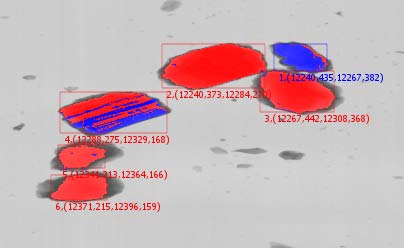

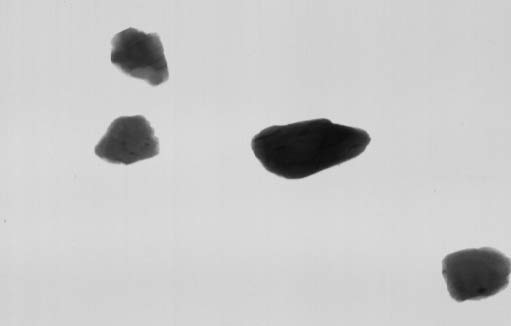

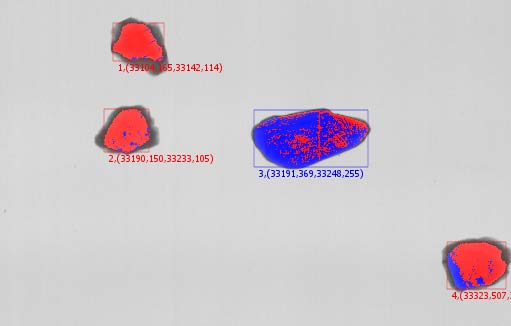

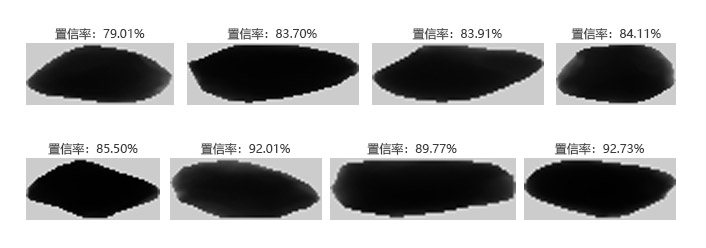

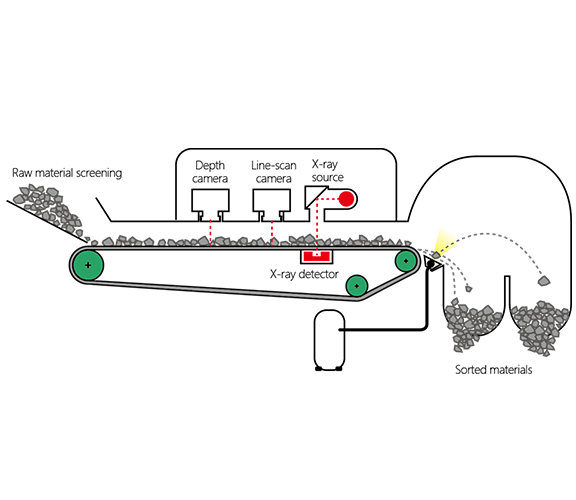

The ore is evenly distributed after sliding down to the conveyor belt through the vibrating feeder. When the ore passes through the x-ray detector, 3D sensor, and line array camera at a constant speed, the data is collected by the recognition system,and it's recognized by its density and neural network algorithm (see the algorithm chapter for details), according to the postion and judgement information, execution system will be notified and separate ores automatically.

X Ray sorting system with simple structure and high precision

The ore is evenly distributed after sliding down to the conveyor belt through the vibrating feeder. When the ore passes through the x-ray detector, 3D sensor, and line array camera at a constant speed, the data is collected by the recognition system,and it's recognized by its density and neural network algorithm (see the algorithm chapter for details), according to the postion and judgement information, execution system will be notified and separate ores automatically.

System Configuration

X Ray sorting system consist of feeding system, identification system, air jet system, dust removal system, control system, and remote management system. We provide a complete system that can be operated independently or a core system that is convenient for integration (including only the feeding system, identification system, elimination system, and centralized control interface)

System Configuration

X Ray sorting system consist of feeding system, identification system, air jet system, dust removal system, control system, and remote management system. We provide a complete system that can be operated independently or a core system that is convenient for integration (including only the feeding system, identification system, elimination system, and centralized control interface)

X Ray sorting system

Widely in use and with great technology advantage Suitable for sorting various ores such as scheelite, wolframite, tin, diamond, coal, rare earth, etc. Suitable for sorting renewable resources such as aluminum, magnesium, stainless steel, circuit boards, slag, etc.

X Ray sorting system

Widely in use and with great technology advantage Suitable for sorting various ores such as scheelite, wolframite, tin, diamond, coal, rare earth, etc. Suitable for sorting renewable resources such as aluminum, magnesium, stainless steel, circuit boards, slag, etc.